Supporting equipment

Product Testing Center

Since its establishment, the company has taken "scientific precision" as its core value. The testing technology center is composed of experienced technicians and rigorous and realistic experimenters to ensure the professionalism of the experiment. The testing center has complete equipment and facilities, and the experimental equipment is strictly calibrated. In a rigorous and standardized manner, the current national standards, specifications and procedures are strictly implemented to ensure the accuracy of inspection data.

Automatic old-fashioned plaster machine

It is suitable for the production of traditional external plaster. The dripping, molding, compounding and cutting links in production are automatically handled by the equipment, which is simple and convenient to operate. Most of the high-precision parts used on the equipment can ensure that the product size error is less than 2%, the patch position error is less than 3%, the finished product rate is as high as over 96%, the equipment action is compact, the efficiency can reach 18 tablets/minute, the smaller the drug core, the higher the efficiency.

automatic coating machine

This equipment has the function of coating compound function completion, and has the advantages of two coating methods that can make the coating amount range wide. The characteristics of high tension control precision, uniform coating, no scratch on the substrate, flat end face of winding and unwinding are as follows: the whole machine adopts electric central control, frequency conversion speed regulation, hot air circulation jet drying and other technologies, and the winding and unwinding parts are automatically loaded and unloaded.

Automatic liquefaction filling production line

It is a large-scale equipment integrating automatic capping, automatic bottle management, automatic bottle loading, automatic filling, automatic capping and automatic labeling. The speed of the machine can be adjusted steplessly to realize automatic operation. At the same time, the bottle discharge of the machine adopts photoelectric sensor detection, which can effectively ensure that the bottles on the bottle discharge conveyor belt will not be blocked and can be conveniently connected into an assembly line. Applicable to the filling requirements of different products, fully automatic touch screen operation, can fill 10mL-100mL liquid products.

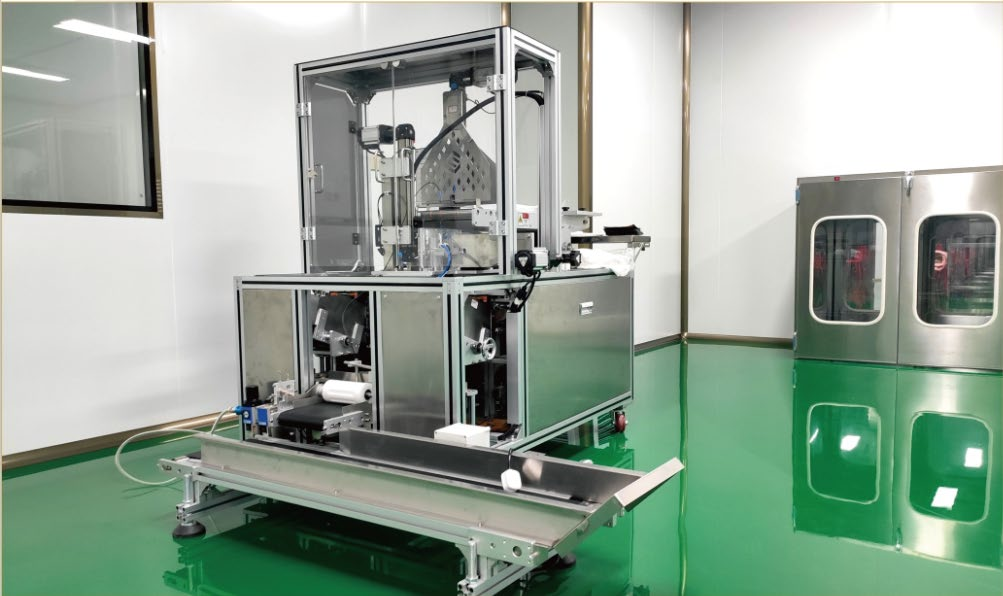

Automatic paste production line

This machine is a full-automatic medicine paste synthesis machine. The device can quickly and continuously synthesize sheet medicine paste from plaster tape raw materials and non-woven empty paste raw materials that are easy to obtain in batches, which greatly improves the production efficiency of medicine paste and realizes complete mechanical automation.

Automatic multi-function drip machine

It is suitable for the production of traditional external plaster. The dripping, molding, compounding and cutting links in production are automatically handled by the equipment, which is simple and convenient to operate. Most of the high-precision parts used on the equipment can ensure that the product size error is less than 2%, the patch position error is less than 3%, and the finished product rate is as high as 96%. The equipment is basically noiseless in operation and can improve the working environment. The equipment has compact connection, the efficiency can reach 18 tablets/minute, and the smaller the core, the higher the efficiency.

Automatic vacuum emulsification equipment

Vacuum homogenization emulsifying machine comprehensive characteristics of domestic and foreign emulsifying machine, the machine adopts SUS304 or SUS316L stainless steel material production, scientific homogeneous structure, reasonable wall mixing, to ensure that the material fully homogeneous emulsification, make the product more delicate, uniform, smooth. High-speed shearing, grinding and crushing are realized under precision coordination. Material paste can be fully delicate and shiny.

Three-layer purified water treatment system

The reverse osmosis process uses a semi-permeable spiral-wound membrane to separate and remove soluble solids from water. Organic matter, colloidal substances and bacteria. The raw water is sent to and passes through the reverse osmosis membrane under a certain pressure, and the water penetrates through the micro pore size of the membrane to obtain pure water after collection. The impurities in the water are concentrated in the cut-off liquid and discharged. The RO membrane removes more than 96 percent of dissolved solids, more than 99 percent of organics and colloids, and almost 100 percent of bacteria.

Automatic hydrogel coating machine

The host of this system is manufactured by industrial-grade components, which can meet the production of various hydrogel products with high dimensional accuracy and processing speed, and adopts a unique control algorithm to maintain the stability and consistency of processing accuracy under the premise of meeting high-efficiency processing.

Automatic mask folding machine

1. The biggest feature of this machine is that it adopts automatic cotton supply, automatic separation of incoming materials, automatic cotton taking, automatic folding and automatic bagging. The whole process without manual participation, one step in place! No need for traditional manual cotton, to achieve a fully automatic machine production. Greatly save the company's labor costs, 3-5 machines at the same time production only need 1 worker to participate in the smooth completion of production, acid and alkali corrosion resistance! The appearance is both beautiful and environmentally friendly.

2. No film, no separation, no folding; No bag, automatic shutdown.

3, reduce manpower, automatic process consistent operation completed, stable quality, stable production capacity.

4. The whole machine is divided into two parts, which can be disassembled and used separately. The membrane part can also be equipped with other cotton folding machines. The cotton folding part can also be used separately by manual cotton placement. The operation is convenient and simple to enhance the image of the factory, lead the trend of industrial automation and enhance the competitive advantage of customers.

Automatic facial mask filling machine

1. Automatic bag lowering, automatic filling, automatic sealing, finished product output, automatic counting, no bag without filling, no bag without sealing;

2. The contact parts are made of stainless steel 316, in line with GMP standards

3. The filling system adopts magnetic gear pump;

4. PLC LCD touch screen control operation, easy to set parameters on the touch screen, clear and intuitive output and error information, digital display temperature control;

5. Electrical and pneumatic components are selected internationally renowned brands.

Water treatment equipment for beverage production line

The system is designed to use multi-media filter, activated carbon filter and security filter as the pre-treatment, effectively remove the raw water suspended solids, sand, particles, silicone colloid, organic matter, odor, residual chlorine and other impurities, so that after ion exchange treatment of water quality in line with industrial production requirements. The finishing system (mixed bed system) is carried out at the back end to make the water quality meet the requirements of production water.

Fully automatic 3 & 5 gallon 3-in -1 equipment

The labeling machine is suitable for all kinds of bottle-shaped fruit juice, tea drinks, dairy products, purified water, condiments, beer, sports drinks and other food and beverage industries. It not only has high accuracy of labeling position, but also can highlight the bottle type after shrinkage. The function of the automatic beverage bottle labeling machine, mineral water bottle labeling machine and juice bottle labeling machine is to automatically put the heat shrinkable label on the bottle, and then put the label on the bottle body through the shrink labeling machine. It has the advantages of saving manpower, reducing labor intensity and improving productivity.

Water Equipment for Drinking Water and Beverage Industry

The water used in the beverage industry usually needs to be pre-treated water or purified water, which meets the sanitary standards for GB17324-2003 bottles (barrels) of purified drinking water.

Main uses: drinking pure water, natural water, beverages, food, low-alcohol liquor blending water, pure draft beer filtration, etc. The equipment is the secondary treatment of tap water, not only to remove a large number of suspended solids, colloids and particles in the water, so that the tap water becomes clean, clear and transparent, but also to remove organic matter, bacteria and Escherichia coli and other pathogenic substances, so that tap water into clean and sanitary drinking water.

Address: South Road, East of Huoyang Avenue, Economic and Technological Development Zone, Ruzhou City, Henan Province

Copyright©2024 Runling Group technical support:www.300.cn SEO

Copyright©2024 Runling Group

Technical Support:www.300.cn SEO

SAF Coolest v1.3.1.2 设置面板 GAGSD-ZGYF-JDSEE-AEX

无数据提示

Sorry, the current column is being updated, please look forward to it!

You can view other columns or returnHome Page